- +44 (0)1473 836 214

- info@acupaq.com

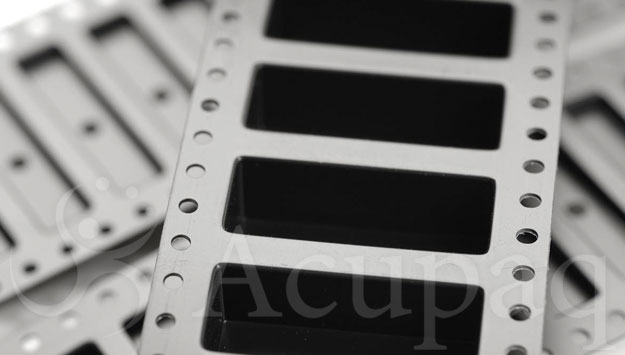

The carrier tape Polycarbonate material provides superior performance, especially in small to micro-form factors requiring very sharp pocket features. ESD-safe polycarbonate maintains its flexibility, stability and strength through time and temperature variations. Type U, G, N and Q carrier tapes are available for standard and clean room compatible applications.

Shelf Life and Storage

We recommend that Polycarbonate carrier tape is used within 5 years of the date of manufacture. Store this product in its original packaging in a climate controlled environment where temperature ranges from 21°C +/- 17°C (70°F +/- 30°F). This product is not affected by humidity. Allow the product to stabilize at room temperature prior to use.

Camber

The Polycarbonate carrier tape meets the EIA-481-D standard for camber that is not greater than 1mm in 250 linear millimeters. For 8mm to 24mm carrier tape in the level wind format, the camber will not be greater than 2mm in 250 linear millimeters.

Polycarbonate Carrier Tape Material Properties

The values presented for this product are typical laboratory data and are subject to change without prior notice.

| Type U | Type G | Type N | Type Q | Test Method | |

| Standard Thickness | 0.20mm | 0.25mm | 0.30mm | 0.33mm | – |

| Specific Gravity | 1.27 g/cc | ASTM D-792 | |||

| Tear Strength | LD 0.38 lb – TD 0.44 lb | ASTM D-1938 [4] | |||

| Elongation | LD 10% – TD 8% | ASTM D-882 [5] | |||

| Tensile Strength | MD 3210 psi – TD 2765 psi | ASTM D-882 [5] | |||

| Vicat Softening | 148°C (298°F) | ASTM D-1525 | |||

| Surface Resistivity | <1012> 104 ohms/square | ASTM D-257 | |||

Cover Tape Compatibility

| Material | AA | AHP | ABX | ATA | PS3 | APC | AHPC |

| D & I Tri-laminate (Polystyrene) | X | X | X |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.