HomeProducts

- +44 (0)1473 836 214

- info@acupaq.com

Type APC Cover Tape is a conductive, pressure sensitive adhesive cover tape designed to protect and confine surface mount components within the pockets of our embossed polycarbonate carrier tapes. APC has a very stable acrylic adhesive that provides a full 2-year shelf life when stored under recommended conditions.

Construction

Type APC Cover Tape is constructed in three layers, a 0.00092″ polyester base film over a 0.0010” pressure sensitive acrylic adhesive, with a 0.00048″ conductive polyester film on the device side.

Configurations

Type APC Cover Tape is provided splice-free on 3” inner diameter plastic cores.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Application Method | Roller @ 2m/min |

| Temperature | Ambient |

| Humidity | Ambient |

| Pressure | 40 PSI |

Shelf Life and Storage

Type APC Cover Tape has a shelf life of 24 months from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate-controlled environment where temperatures do not exceed 25°C (75°F) and relative humidity is under 80%. Exceeding these recommended storage conditions could result in inconsistent product performance.

Type APC Pressure Sensitive Conductive Cover Tape Material Properties

1 Tests performed under specific sealing conditions on formed polycarbonate tape

** Aging at 52°C and 95% PH increased adhesion to carrier by 80%

Note: The values presented for this product are typical laboratory data and may be changed without notice.

| Properties | Typical Value | Test Method / Standard |

| Overall Thickness | 0.0024″ (0.061mm) | ASTM D-374 |

| Initial Adhesion to Carrier** (Mean Value) |

5.4mm: 45 +/- 10 grams 9.3mm, 13.3mm, 21.3mm: 60 +/- 15 grams >/= 25.5mm: 70 +/- 20 grams |

EIA-481-B |

| Surface Resistivity | Adhesive side: <1012 ≥105 ohms/square Back side: non conductive |

ASTM D-257 |

| Minimum Strength Break | 30 pounds/inch of width | ASTM D-882 |

| Elongation | 1 | ASTM D-882 |

| Overall Width Tolerance | +/- 0.10mm | Laser Micrometer |

| Adhesion Edge Tolerance | +/- 0.20mm | Laser Micrometer |

| Transparency | <10% Haze | ASTM D-1003 |

| Colour | Transparent Metallised Film | N/A |

| Part Number | Tape Width (+/- 0.10) | Adhesive Width / Side | Roll Length | Rolls Per Box |

| APC0054-300 | 5.4mm | 0.70mm | 300 | 50 |

| APC0093-300 | 9.3mm | 1.0mm | 300 | 30 |

| APC0133-xxx | 13.3mm | 1.0mm | 300 & 500 | 15 |

| APC0213-xxx | 21.3mm | 1.0mm | 300 & 500 | 10 |

| APC0255-xxx | 25.5mm | 1.5mm | 300 & 500 | 10 |

| APC0375-xxx | 37.5mm | 1.5mm | 300 & 500 | 5 |

| APC0495-xxx | 49.5mm | 1.5mm | 300 & 500 | 5 |

| APC0655-xxx | 65.5mm | 2.0mm | 300 & 500 | 4 |

| APC0815-xxx | 81.5mm | 2.0mm | 300 & 500 | 3 |

| APC0975-xxx | 97.5mm | 2.0mm | 300 & 500 | 2 |

*Note: Part number for 13.3mm and wider is dependent on roll length; use 300 or 500 in place of “xxx”.

Download PDF spec sheet of this product hereFor further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type AHPC Cover Tape is a clear, antistatic, heat sealable cover tape engineered to protect and confine surface mount components contained in our carrier tape. AHPC is designed to adhere at various temperatures and dwell times within industry standards.

Construction

Type AHPC Cover Tape is constructed in two layers, a 0.00092” polyester base film covered by a 0.00128” heat-activated adhesive coating layer. Both layers are antistatic to protect static sensitive devices.

Configurations

Type AHPC Cover Tape is provided splice-free on 3” inner diameter plastic cores.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Temperature | 170° – 200° C |

| Dwell Time | 0.2 – 0.5 sec |

| Pressure | 30 – 35 PSI |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) |

Shelf Life and Storage

Type AHPC Heat Activated Antistatic Cover Tape has a shelf life of 24 months from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate-controlled environment where temperatures do not exceed 40°C (104°F) and relative humidity is under 80%.

Type AHPC Heat Activated Antistatic Cover Tape Material Properties

1 Tests performed under specific sealing conditions on formed polycarbonate tape.

** Aging at 52°C and 95% PH increased adhesion to carrier by 80%

Note: The values presented for this product are typical laboratory data and may be changed without notice.

| Properties | Typical Value | Test Method / Standard |

| Initial Adhesion to Carrier ** | 35 to 55 grams | EIA-481-B |

| Surface Resistivity | <1012>=105 ohms/square (both sides) | ASTM D-257 |

| Tensile Strength | 11,000 PSI | ASTM D-882 |

| Elongation | 120 – 140% | ASTM D-882 |

| Overall Width Tolerance | +/- 0.10mm | Laser Micrometer |

| Transparency | <27% Haze | ASTM D-1003 |

| Colour | Natural, non-pigmented | N/A |

| Part Number | Tape Width (+/- 0.10) | Roll Length (m) | Pack Size |

| AHPC0054-300 | 5.4mm | 300 | 50 |

| AHPC0093-300 | 9.3mm | 300 & 500 | 30 |

| AHPC0133-xxx | 13.3mm | 300 & 500 | 15 |

| AHPC0213-xxx | 21.3mm | 300 & 500 | 10 |

| AHPC0255-xxx | 25.5mm | 300 & 500 | 10 |

| AHPC0375-xxx | 37.5mm | 300 & 500 | 5 |

| AHPC0495-xxx | 49.5mm | 300 & 500 | 5 |

| AHPC0655-xxx | 65.5mm | 300 & 500 | 4 |

| AHPC0815-xxx | 81.5mm | 300 & 500 | 3 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

PS3 is an antistatic, transparent, pressure sensitive adhesive cover tape engineered to protect and fonfine surface mount components contained in our polystyrene carrier tapes.

Construction

Type PS3 Cover Tape is constructed in three layers, a 0.00092” polyester base film covered by a 0.00050” pressure sensitive acrylic adhesive, with a 0.00048” antistatic polyester film on the device side.

Configurations

Type PS3 Cover Tape is provided splice-free on 3” inner diameter plastic cores.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Application Method | Rolelr @ 2m/min |

| Temperature | Ambient |

| Humidity | Ambient |

| Pressure | 40 PSI |

Shelf Life and Storage

Type PS3 Pressure Sensitive Antistatic Cover Tape has a shelf life of 24 months from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate-controlled environment where temperatures do not exceed 40°C (104°F) and relative humidity is under 80%. Exceeding these recommended storage conditions could result in inconsistent product performance.

Type PS3 Pressure Sensitive Antistatic Cover Tape Material Properties

1 Tests performed under specific sealing conditions on formed polycarbonate tape

** Aging at 52°C and 95% PH increased adhesion to carrier by 80%

Note: The values presented for this product are typical laboratory data and may be changed without notice.

| Properties | Typical Value | Test Method / Standard |

| Overall Thickness | 0.0019″ (0.048mm) | ASTM D-374 |

| Initial Adhesion to Carrier** | 45 +/- 15g 1 (<5.5mm width) 60 +/- 20g 1 (<21.3mm width) 85 +/- 25g 1 (>25.5mm width) |

EIA-481-B |

| Surface Resistivity | Adhesive side: = <1012> 105 ohms/square Back side: non conductive |

ASTM D-257 |

| Minimum Strength Break | 20 pounds/inch of width | ASTM D-882 |

| Elongation | 100% minimum | ASTM D-882 |

| Overall Width Tolerance | +/- 0.10mm | Laser Micrometer |

| Adhesion Edge Tolerance | +/- 0.20mm | Laser Micrometer |

| Transparency | <20% Haze | ASTM D-1003 |

| Colour | Transparent | N/A |

| Part Number | Tape Width (+/- 0.10) | New Meters Per Roll |

| NS05406SP | 5.4mm | 200 |

| NS05506SP | 9.2mm | 200, 480 |

| NS09506SP | 9.5mm | 200, 480 |

| NS13306SP | 13.3mm | 200 |

| NS13506SP | 13.5mm | 200 |

| NS21006SP | 21.0mm | 200 |

| NS25506SP | 25.5mm | 200 |

| NS37506SP | 37.5mm | 200 |

| NS49506SP | 49.5mm | 200 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type S Cover Tape is a transparent, heat sealable polyester cover film engineered to protect and contain surface mount components in a wide range of both conductive and non conductive carrier tapes. Type S Cover Tape’s adhesive system has been proven, with millions of meters of defect-free product manufactured and sold since 1986.

Construction

Type S Cover Tape is constructed in two layers, a 0.00092” polyester base film covering a 0.0015” heat-activated adhesive coating layer (total 0.062mm nominal).

Configurations

Type S Heat Activated Non-Antistatic Cover Tape is provided splice-free on 3” inner diameter plastic cores. Available widths include all EIA standard widths for carrier tapes from 8mm to 56mm.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Temperature | 170° – 200° C |

| Dwell Time | 0.1 – 1.0 sec |

| Pressure | 30 – 35 PSI |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) |

Shelf Life and Storage

Type S Cover Tape has a shelf life of 1 year from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate controlled environment with temperatures between 4°C and 38°C (39°F – 100°F) and relative humidity under 80%.

Type S Heat Activated Non Antistatic Cover Tape Material Properties

The values presented for this product are typical laboratory data and may be changed without notice. 1Tests performed under specific sealing conditions.

| Properties | Typical Value | Test Method / Standard |

| Adhesion to Carrier | 40 +/- 30 grams1 | EIA-481-B |

| Surface Resistivity | N/A | ASTM D-257 |

| Tensile Strength | 3.2kg/cm width | ASTM D-882 |

| Elongation | 1 | ASTM D-882 |

| Gauge | 0.062 +/- 0.007mm | ASTM D-374 |

| Colour | Natural, non-pigmented | – |

| Standard Roll | 3″ I.D. core | – |

| Part Number | Tape Width (+/- 0.10) | New Meters Per Roll |

| NS05406SP | 5.4mm | 200 |

| NS05506SP | 9.2mm | 200, 480 |

| NS09506SP | 9.5mm | 200, 480 |

| NS13306SP | 13.3mm | 200 |

| NS13506SP | 13.5mm | 200 |

| NS21006SP | 21.0mm | 200 |

| NS25506SP | 25.5mm | 200 |

| NS37506SP | 37.5mm | 200 |

| NS49506SP | 49.5mm | 200 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type ATA™ Cover Tape offers excellent clarity and highly consistent adhesion. Its smooth adhesive finish refracts little light, greatly enhancing the tape’s clarity while reducing its haze. These features improve your ability to conduct post-taping in-pocket inspection of components. ATA also works with polycarbonate carrier tape.

Construction

Type ATA™ Cover Tape is constructed in two layers, a 0.0010” polyester base film over a 0.0015” heat-activated adhesive coating layer. Both layers are antistatic to protect static sensitive devices.

Configurations

Type ATA™ Heat Activated Cover Tape rolls are 480 splice-free meters on a 3” inner diameter plastic core.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Polystyrene | Polycarbonate | |

| Temperature | 160° – 180° C | 200° – 210° C |

| Dwell Time | 0.2 – 0.5 sec | 0.3 – 0.5 sec |

| Pressure | 30 – 35 PSI | |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) | 0.015 – 0.020″ (0.38 – 0.51 mm) |

:

Shelf Life and Storage

Type ATA™ Heat Activated Antistatic Cover Tape has a shelf life of 24 months from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate-controlled environment where temperatures do not exceed 40°C (104°F) and relative humidity is under 80%. Exceeding these recommended storage conditions could result in inconsistent product performance.

Type ATA™ Heat Activated Antistatic Cover Tape Material Properties

The values presented for this product are typical laboratory data and may be changed without notice. 1Tests performed under specific sealing conditions on polystyrene tape.

| Properties | Typical Value | Test Method / Standard |

| Adhesion to Carrier | 50 +/- 20 grams1 | EIA-481-B |

| Surface Resistivity | =105 ohms/square (both sides) | ASTM D-257 @ 50% RH |

| Tribo-electric Potential | 50 volts max | RS481-A |

| Tensile Strength | 8,100 PSI | ASTM D-882 |

| Elongation | 110% +/- 10% | ASTM D-882 |

| Transparency | 90% Transmittance | ASTM D-1003 |

| 89% Clarity | ||

| 20% Haze | ||

| Colour | Natural, non-pigmented | – |

| Standard Roll | 3” I.D. core, 480 meters | – |

| Part Number | Tape Width (+/- 0.10) |

| ATA0054 | 5.4mm |

| ATA0092 | 9.2mm |

| ATA0133 | 13.3mm |

| ATA0210 | 21.0mm |

| ATA0255 | 25.5mm |

| ATA0375 | 37.5mm |

| ATA0495 | 49.5mm |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type AHP Cover Tape is an antistatic, transparent, heat sealable cover tape which protects and confines surface mount components contained in our embossed carrier tape. Suitable for any heat sealing taping application, AHP Cover Tape provides consistent adhesion and a proven record of quality.

Construction

Type AHP Cover Tape is constructed in two layers, a 0.00092″ polyester base film covered by a 0.00128” heat activated adhesive coating layer. Both layers are antistatic to protect static sensitive devices.

Configurations

Type AHP Cover Tape is provided standard with 300 and 500 splice-free meters on a 3” inner diameter plastic core. Available widths include all EIA standard widths for carrier tapes between 8mm and 56mm. Additional widths may be available by special request.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Temperature | 165° – 210° C |

| Dwell Time | 0.1 – 1.0 sec |

| Pressure | 30 PSI |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) |

Shelf Life and Storage

Type AHP Cover Tape has a shelf life of 24 months from the date of manufacture when kept in recommended conditions. Store this product in its original packaging in a climate-controlled with temperatures between 19°C – 40°C (66°F – 104°F) and relative humidity is 50% +/- 30%. Do not store in direct sunlight. Allow product to stabilize at room temperature prior to use. Exceeding these recommended storage conditions could result in inconsistent product performance.

Type AHP Heat Activated Antistatic Cover Tape Material Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice.

1Tests performed under specific sealing conditions on polystyrene tape.

| Properties | Typical Value | Test Method / Standard |

| Initial Adhesion to Carrier | 50 +/- 20 grams1 | EIA-481-B |

| Surface Resistivity | =105 ohms/square (both sides) | ASTM D-257 @ 50% RH |

| Tensile Strength | 11,000 PSI | ASTM D-882 |

| Elongation | 120 – 140% | ASTM D-882 |

| Transparency | 91% Transmittance 25% Clarity 50% Haze |

ASTM D-1003 |

| Colour | Transparent, pale blue | – |

| Part Number | Tape Width (+/- 0.10) |

| AHP0053-300 | 5.3mm |

| AHP0054-300 | 5.4mm |

| AHP0092-300 | 9.2mm |

| AHP0133-300 | 13.3mm |

| AHP0210-300 | 21.0mm |

| AHP0213-300 | 21.3mm |

| AHP0255-300 | 25.5mm |

| AHP0375-300 | 37.5mm |

| AHP0495-300 | 49.5mm |

| AHP0655-300 | 65.5mm |

| AHP0815-300 | 81.5mm |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type ABx™ heat-activated antistatic cover tape is a high-quality, low-cost product developed to reduce the tendency to bond to areas other than the seal tracks. This condition is known as ‘wetting’ and causes unpredictable or unstable peel force as well as visual concerns.

Construction

Type ABx™ Cover Tape is constructed in two layers, a 0.0010” thick polyester base film covered by a 0.0011” thick heat-activated adhesive coating layer. Both layers are antistatic to protect static sensitive devices.

Configurations

Type ABx™ Heat Activated Cover Tape is provided with 300, 500 and 1000 splice-free meters on a 3” inner diameter plastic core. Widths available include all EIA standard widths for carrier tapes between 8mm and 120mm. Additional widths may be available by special request.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Temperature | 170° – 210° C |

| Dwell Time | 0.2 – 0.50 sec |

| Pressure | 30 – 35 PSI |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) |

Shelf Life and Storage

Type ABx™ Cover Tape has a shelf life of 24 months from the date of manufacture when stored under the recommended condition. We recommend storing this product in its original packaging in a climate-controlled environment with temperatures between 19°C and 40°C (66° – 104°F) and relative humidity under 80%.

Type ABx™ Heat Activated Antistatic Cover Tape Material Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice.

1 Tests performed under specific sealing conditions on polystyrene tape.

| Properties | Typical Value | Test Method / Standard |

| Adhesion to Carrier | 50 +/- 20 grams1 | EIA-481-B |

| Surface Resistivity | =105 ohms/square (both sides) | ASTM D-257 @ 50% RH |

| Tribo-electric Potential | 50 volts max | RS481-A |

| Tensile Strength | 11,000 PSI | ASTM D-882 |

| Elongation | 120 – 140% | ASTM D-882 |

| Transparency | 93% Transmittance 35% Clarity 51% Haze |

ASTM D-1003 |

| Colour | Natural, non-pigmented | |

| Standard Roll | 3″ I.D. core, 300 meters |

| Part Number | Tape Width (+/- 0.10) |

| ABX0054 | 5.4mm |

| ABX0092 | 9.2mm |

| ABX0133 | 13.3mm |

| ABX0210 | 21.0mm |

| ABX0255 | 25.5mm |

| ABX0375 | 37.5mm |

| ABX0495 | 49.5mm |

| ABX0655 | 65.5mm |

| ABX0815 | 81.5mm |

| ABX1135 | 113.5mm |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

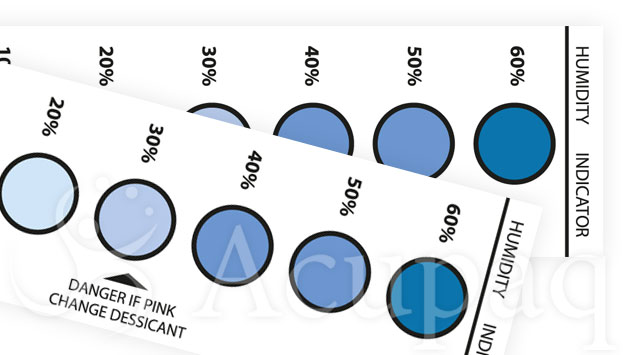

These HICs are Cobalt-Dichloride (CoCL₂) free allowing them to be used as regular HICs without the limitations caused by the chemical regulations under the European Chemical Bureau (ECB) REACH directives. They are as effective and accurate as HICs that contain the chemical so do not give a second rate reading. Some companies desire the used of HICs that are Cobalt-Dichloride Free for their moisture sensitive products, which include: semiconductors, electronics, optics, radar and various defense systems.

Features:

Typical Applications:

| Indication at: | 2% RH Environment: | 5% RH Environment: | 10% RH Environment: | 60% RH Environment: | 65% RH Environment: |

| 5% Spot | Blue (Dry) | Lavender (Spot Value) | Pink (Wet) | Pink (Wet) | Pink (Wet) |

| 10% Spot | Blue (Dry) | Blue (Dry) | Lavender (Spot Value) | Pink (Wet) | Pink (Wet) |

| 60% Spot | Blue (Dry) | Blue (Dry) | Blue (Dry) | Lavender (Spot Value) | Pink (Wet) |

| Product Code | Description | Indicates (%RH) | Size (inch) | Pack Size |

| ANT051060-CDF | 3 spot HIC- Cobalt-Dichloride Free | 5, 10, 60 | 2 x 3 | 125 |

| ANT051015-CDF | 3 spot HIC- Cobalt-Dichloride Free | 5, 10, 15 | 2 x 3 | 125 |

| ANT826004NE-CDF | 6 spot HIC- Cobalt-Dichloride Free | 10, 20, 30, 40, 50, 60 | 2 x 3 | 125 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

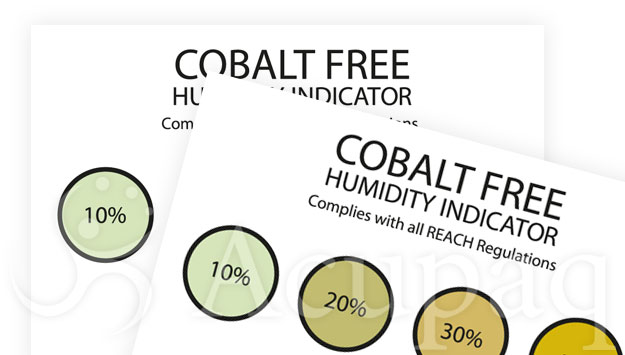

Humidity Indicator Cards (HICs) are used to indicate the humidity levels inside a moisture barrier bag after it has been vacuum packed. The 6 indicator spots change colour to indicate the relative humidity present.

Being Cobalt free makes these cards environmentally friendly while maintaining the same level of reading as those that contain Cobalt.

Features:

| Product Code | Indicates (%RH) | Size (inch) | Pack Size |

| ANT826004NE-H, CF | 10, 20, 30, 40, 50, 60 | 4.72 x 1.77 | 200 |

| ANT826004NE | 10, 20, 30, 40, 50, 60 | 1.56 x 4.60 | 200 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Humidity Indicator Cards (HICs) are used to indicate the humidity levels inside a moisture barrier bag after it has been vacuum packed. The 4 indicator spots change colour to indicate the relative humidity present. Being Cobalt free makes these cards environmentally friendly while maintaining the same level of reading as those that contain Cobalt.

Features:

| Product Code | Description | Indicates (%RH) | Size (inch) | Pack Size |

| ANTHM-04 | 4 Spot HIC: Specifically designed for use in the electronics industry and is perfect for use with components using the “Dry Pack” packaging concept. | 10, 20, 30, 40 | 2 x 3 | 100 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.