HomeProducts

- +44 (0)1473 836 214

- info@acupaq.com

Our exclusive Tri-Laminate PS+C (Polystyrene with Carbon) carrier tape provides devices maximum protection from physical and ESD damage during shipping and storage. Tri-Laminate PS+C carrier tape is available in a variety of thicknesses, enabling selection of the best material for the broadest range of design applications.

Shelf Life and Storage

We recommend that Tri-Laminate PS+C carrier tapes be used within 5 years of the date of manufacture. Store this product in its original packaging in a climate controlled environment where temperature ranges from 21°C +/- 17°C (70°F +/- 30°F). This product is not affected by humidity. Allow the product to stabilize at room temperature prior to use.

Camber

The Tri-Laminate PS+C series meets the EIA-481-D standard for camber that is not greater than 1mm in 250 linear millimeters. For 8mm to 24mm carrier tape in the level wind format, the camber will not be greater than 2mm in 250 linear millimeters.

Tri-Laminate PS+C Carrier Tape Material Properties

The values presented for this product are typical laboratory data and may be changed without notice.

| Type V | Type W | Type C | Type X | Type T | Test Method | |

| Standard Thickness | 0.21mm | 0.25mm | 0.30mm | 0.35mm | 0.50mm | – |

| Specific Gravity | 1.06 g/cc | ASTM D-792 | ||||

| Tear Strength | LD 0.53 lb – TD 0.61 lb | ASTM D-1938 [4] | ||||

| Elongation | LD 65% – TD 14% | ASTM D-882 [5] | ||||

| Tensile Strength | LD 6575 psi – TD 6445 psi | ASTM D-882 [5] | ||||

| Vicat Softening | 107°C (225°F) | ASTM D-1525 | ||||

| Surface Resistivity | <1012>105 ohms/square | ASTM D-257 Static Dissipative per EIA 541 |

||||

Cover Tape Compatibility

| Material | AA | AHP | ABX | ATA | PS3 | APC | AHPC |

| C,W, X, V & T Tri-laminate (Polystyrene + Carbon) | X | X | X | X | X |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Type AA® Cover Tape is an antistatic, transparent, heat sealable cover film. It is engineered to protect and contain surface mount components in embossed polystyrene carrier tapes.

Construction

Type AA® Cover Tape contains a top layer of 0.00092” thick polyester base film and a bottom layer of 0.00128” thick heat activated adhesive coating layer. Both layers are antistatic to ensure the protection of static sensitive devices.

Configurations

Type AA® Heat Activated Cover Tape is provided standard with 300, 400, 500, 600 and 1000 splice-free meters on a 3” inner diameter plastic core. Widths available include all EIA standard widths for carrier tapes between 8mm and 56mm, plus custom widths by special request.

Recommended Sealing Conditions

The detailed sealing parameters apply to single strike seal mode. Multi-strike, or overlap sealing, may require adjustment outside of these ranges.

| Temperature | 170° – 210° C |

| Dwell Time | 0.25 – 0.40 sec |

| Pressure | 30 – 35 PSI |

| Seal Rail Width | 0.015 – 0.020″ (0.38 – 0.51 mm) |

Shelf Life and Storage

We recommend that the AA® Cover Tape be used within 24 months from the date of manufacture. Store this product in its original packaging in a climate-controlled environment with temperatures under 50°C (122° F) and relative humidity under 80%. Do not store in direct sunlight or excess temperature/humidity for prolonged periods of time. Allow the product to stabilize at room temperature prior to use.

Type AA™ Heat Activated Antistatic Cover Tape Material Properties

The values presented for this product are typical laboratory data and may be changed without notice. 1 Tests performed under specific sealing conditions on polystyrene tape.

| Properties | Typical Value | Test Method / Standard |

| Adhesion to Carrier | 40 +/- 30 grams1 | EIA-481-B |

| Surface Resistivity | <1012>=105 ohms/square (both sides) | ASTM D-257 @ 50% RH |

| Tribo-electric Potential | 50 volts max | RS481-A |

| Tensile Strength | 10,000 PSI | ASTM D-882 |

| Elongation | 100% | ASTM D-882 |

| Transparency | 90% Transmittance 16% Clarity 59% Haze |

ASTM D-1003 |

| Colour | Transparent, pale blue | – |

| Part Number | Tape Width (+/- 0.10) |

| AA05405NP | 5.4mm |

| AA09205NP | 9.2mm |

| AA13305NP | 13.3mm |

| AA21005NP | 21.0mm |

| AA25505NP | 25.5mm |

| AA37505NP | 37.5mm |

| AA49505NP | 49.5mm |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

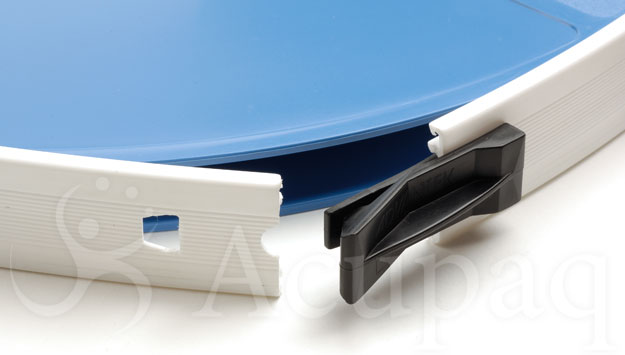

LOKBAND® offers superior protection for components packaged in tape and reel. The band fastens to the outer edges of either a 13″ or 22″ reel, preventing the flanges from crushing together during dry-pack or handling. The LOKBAND® also keeps the reel from unwinding if the protective wrap on the carrier tape detaches. The LOKBAND® fits most 12mm, 16mm, 24mm, 32mm, 44mm and 56mm wide 13″ or 22″ diameter reels. It is secured around the outer reel edge by snapping the edge together with an attached clip.

Configuration

The LOKBAND® is available in lengths designed for use with either a 13″ or 22″ diameter plastic reel. Lengths are 1,035mm (40.75″) for a 13″ reel and 1,750mm (68.90″) for a 22″ reel. The width of the LOKBAND is dependent upon the width of the reel being used. The LOKBAND® for use with both 13″ and 22″ reels are available for EIA standard carrier tape widths from 12mm to 56mm. (Note: 12mm and 16mm are not available for 22″ LOKBAND®.)

Tape WidthW0 (mm)W1 (mm)12mm12.72116mm16.72524mm24.73332mm32.74144mm44.75356mm56.756.7

Shelf Life and Storage

We recommend that the LOKBAND® be used within 24 months from the date of manufacture. Store this product in its original packaging in a climate controlled environment where temperature ranges from 21°C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. This product is not affected by humidity.

LOKBAND™ Material Properties

Note: The values presented for this product are typical laboratory data and are subject to change without prior notice. The bands are antistatic coated through immersion in solution. Re-use of this product may degrade the antistatic properties.

| Property | Typical Value | Test Method / Standard |

| Surface Resistivity | ASTM D-257 | N/A |

| Material (Band) | Low Density Polyethylene (LDPE) | N/A |

| Material (Clip) | Polypropylene | N/A |

| Shelf Life (Antistatic Protection) | 24 months | N/A |

| Colour (Band) | White or Blue | N/A |

| Colour (Clip) | Black | N/A |

LOKBAND™ Part Numbers (For use with 13″ Reels)

| Part Number | Width (mm) | Length (mm) | Pack Size |

| LB10412AD | 12 | 1,035mm (40.75″) | 165 |

| LB10416AD | 16 | 1,035mm (40.75″) | 150 |

| LB10424AD | 24 | 1,035mm (40.75″) | 120 |

| LB10432AD | 32 | 1,035mm (40.75″) | 90 |

| LB10444AD | 44 | 1,035mm (40.75″) | 75 |

| LB10456AD | 56 | 1,035mm (40.75″) | 60 |

LOKBAND™ Part Numbers (For use with 22″ Reels)

| Part Number | Width (mm) | Length (mm) | Pack Size |

| LB17524AD | 24 | 1,750mm (68.90”) | 80 |

| LB17532AD | 32 | 1,750mm (68.90”) | 60 |

| LB17544AD | 44 | 1,750mm (68.90”) | 50 |

| LB17556AD | 56 | 1,750mm (68.90”) | 40 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

When you need a high volume of components per reel, choose the 22″ LOKREEL® Jumbo. The LOKREEL® Jumbo reel’s all-plastic construction makes it ideal for particle-sensitive environments where paper or cardboard reels are not suitable. The Jumbo reel’s sturdy design and high-impact injection-molded polystyrene construction combine to offer exceptional protection to packaged components.

Configuration

LOKREEL® Jumbo reels have an outer diameter of 22″ (559mm) and come with a 1″ (26mm) diameter arbor hole. The reel hub measures 7″ (178mm) in diameter and is available in EIA standard widths of 16mm, 24mm, 32mm, 44mm and 56mm.

Shelf Life and Storage

We recommend LOKREEL® Jumbo reels be used within two years from the date of manufacture. Store this product in its original packaging in a climate-controlled environment where temperature ranges from 21° C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

22″ LOKREEL® Jumbo Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice.

* Excessive handling may reduce the static dissipative properties.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,500 PSI | ASTM D-638 |

| Elongation | 40% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 98°C (185°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | White | N/A |

| Description | Part Number | Pack Size |

| 16mm Hub | 140956 | 60 |

| 22″ Molded plastic flange 1″ arbor hole | 140957 | 16 |

| 24mm Hub | 140958 | 40 |

| 32mm Hub | 140959 | 32 |

| 44mm Hub | 140960 | 24 |

| 56mm Hub | 140961 | 20 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Ideal for taking up more component devices in a single reel, the 15” LOKREEL® Ultra is injection-molded using specially formulated high impact polystyrene (HIPS) material and finished with an application of an anti-static agent for ESD protection. An assembled reel is comprised of two inter-locking flanges suitable for winding and transporting carrier tapes packaged with components. Each LOKREEL® Ultra flange is built with the same durable structure as our premium 13” LOKREEL® PRO.

(Note: this reel is not designed to be unsnapped)

Configuration

LOKREEL® Ultra reels have an outer diameter of 15” (381mm) and a 1/2″ (13mm) diameter arbor hole. The hub diameter is 6″ (152mm), suitable for most carrier tapes. Reel halves are available in a variety of hub diameters and hub widths. Hub widths include 4mm, 8mm, 16mm and 28mm, which combine to produce reels for EIA standard carrier tape width of 8mm, 12mm, 16mm, 24mm, 32mm, 44mm and 56mm. The table demonstrates LOKREEL® Ultra half combination and the reel widths they produce.

| Reel Width (mm) | LOKREEL® Pro Flange Combinations |

| 8 | 4 + 4mm |

| 12 | 4 + 8mm |

| 16 | 8 + 8mm |

| 24 | 8 + 16mm |

| 32 | 16 + 16mm |

| 44 | 16 + 28mm |

| 56 | 28 + 28mm |

Shelf Life and Storage

We recommend that LOKREEL® Ultra reels be used within two years from the date of manufacture. Store this product in its original packaging in a climate-controlled environment where temperature ranges from 21° C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

Antistatic LOKREEL® Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice.

* Excessive handling may reduce the static dissipative properties.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,500 PSI | ASTM D-638 |

| Elongation | 40% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 98°C (185°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | White | N/A |

| Hub Width | 4″ Diameter Hub | Pack Size |

| 4mm | RD38604SW | 40 |

| 8mm | RD38608SW | 40 |

| 16mm | RD38616SW | 30 |

| 28mm | RD38628SW | 30 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

LOKREEL® Lite plastic injection-molded packaging reels are an exceptional choice where price is a key concern. LOKREEL® Lite reels are designed to achieve a combination of structural integrity, lower weight and lower cost than the premium reels. The LOKREEL® Lite is built with the same durable hub structure as the premium LOKREEL® Pro. The flanges have larger windows to reduce the amount of plastic used and yet still support up to three labels as large as 3″ x 4″ (75mm x 100mm) each.

Configuration

LOKREEL® Lite reels have an outer diameter of 13″ (330mm) and a 1/2″ (13mm) diameter arbor hole. The hub diameter is 4″ (102mm), suitable for most carrier tapes. Reel halves are available in a variety of hub widths from 4mm, 8mm, 16mm and 28mm, and combining of any two widths would produce a reel for EIA standard carrier tape with width of 8mm, 12mm, 16mm, 24mm, 32mm, 44mm or 56mm. The table demonstrates LOKREEL® Lite half combinations and the reel widths they produce.

| Reel Width (mm) | LOKREEL® Pro Flange Combinations |

| 8 | 4 + 4mm |

| 12 | 4 + 8mm |

| 16 | 8 + 8mm |

| 24 | 8 + 16mm |

| 32 | 16 + 16mm |

| 44 | 16 + 28mm |

| 56 | 28 + 28mm |

Shelf Life and Storage

We recommend RD series Antistatic LOKREEL® products be used within two years from the date of manufacture. Store this product in its original packaging in a climate controlled environment where temperature ranges from 21° C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

Antistatic LOKREEL® Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice.

* Excessive handling may reduce the static dissipative properties.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,500 PSI | ASTM D-638 |

| Elongation | 40% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 98°C (210°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | Navy Blue | N/A |

| Hub Width | 4″ Diameter Hub | Pack Size |

| 4mm | RD33404NB | 50 |

| 8mm | RD33408NB | 50 |

| 16mm | RD33416RB | 50 |

| 28mm | RD33428RB | 40 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

LOKREEL® component packaging reels are ideal for shipment and storage of any component packaged in carrier tape. For this product, we utilise a blend of virgin and regrind high impact polystyrene (HIPS) material that offers high quality and exceptional protection at a reduced price.

Configuration

LOKREEL® Pros have an outside diameter of 13″ (330mm) and a 1/2″ (13mm) diameter arbor hole. Reel halves are available in a variety of hub diameters and hub widths. Hub diameters include the standard 4″ (102mm) hub suitable for most carrier tapes and the 7″ (178mm) hub designed to protect devices contained in deep pocket and narrow pitch carrier tapes. Available hub widths include 4mm, 8mm, 16mm and 28mm. Any combination of these hub widths will combine to produce a reel for EIA standard carrier tape widths of 8, 12, 16, 24, 32, 44 and 56mm. The table demonstrates LOKREEL® Pro half combinations and the reel widths they produce.

| Reel Width (mm) | LOKREEL® Pro Flange Combinations |

| 8 | 4 + 4mm |

| 12 | 4 + 8mm |

| 16 | 8 + 8mm |

| 24 | 8 + 16mm |

| 32 | 16 + 16mm |

| 44 | 16 + 28mm |

| 56 | 28 + 28mm |

Shelf Life and Storage

We recommend that HIPS Regrind LOKREEL® reels be used within two years from the date of manufacture. Store this product in its original packaging in a climate-controlled environment where temperature ranges from 21° C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

Antistatic LOKREEL® Properties

Note: The values presented for this product are typical laboratory data and may be changed without notice. Re-use of this product may degrade the antistatic properties.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,900 PSI | ASTM D-638 |

| Elongation | 45% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 85°C (185°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | Blue | N/A |

| Hub Width | 4″ Diameter Hub | 7″ Diameter Hub |

| 4mm | RD33004RB | – |

| 8mm | RD33008RB | RD33708RB |

| 16mm | RD33016RB | RD33716RB |

| 28mm | RD33028RB | RD33728RB |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

LOKREEL® Pro component packaging reels are ideal for shipment and storage of any component packaged in carrier tape. The LOKREEL® Pro high-impact injection molded polystyrene construction offers exceptional protection to devices. LOKREEL® Pros are sold and shipped disassembled in halves to minimize shipping cost and provide compact storage.

Construction

LOKREEL® Pro halves are injection-molded using a specially formulated high impact polystyrene (HIPS). Antistatic agent is applied to RD series LOKREEL® Pros by emersion in solution. Re-use of this product may degrade the antistatic properties.

Configuration

LOKREEL® Pros have an outside diameter of 13″ (330mm) and a 1/2″ (13mm) diameter arbor hole. Reel halves are available in a variety of hub diameters and hub widths. Hub diameters include the standard 4″ (102mm) hub suitable for most carrier tapes and the 7″ (178mm) hub designed to protect devices contained in deep pocket and narrow pitch carrier tapes. Available hub widths include 4mm, 8mm, 16mm and 28mm. Any combination of these hub widths will combine to produce a reel for EIA standard carrier tape widths of 8, 12, 16, 24, 32, 44 and 56mm. The table demonstrates LOKREEL® Pro half combinations and the reel widths they produce.

Shelf Life and Storage

We recommend that type RD Antistatic LOKREEL® Pros be used within 2 years of the date of manufacture. Type RC Conductive LOKREEL® Pros have an indefinite shelf life. Store this product in its original packaging in a climate controlled environment where temperature ranges from 21° C +/- 17°C (70° +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

Antistatic LOKREEL® Pro Properties

The values presented for this product are typical laboratory data and may be changed without notice.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,900 PSI | ASTM D-638 |

| Elongation | 45% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 85°C (185°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | White | N/A |

Conductive LOKREEL® Pro Properties

The values presented for this product are typical laboratory data and may be changed without notice.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,500 PSI | ASTM D-638 |

| Elongation | 50% | ASTM D-638 |

| Flexural Modulus | 270,000 PSI | ASTM D-790 |

| Vicat Softening | 85°C (185°F) | ASTM D-1525 |

| Specific Gravity | 1.06 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤105 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Colour | Black | N/A |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

7″ component packaging reels provide excellent protection when shipping small components packaged in carrier tape, such as bare die and small integrated circuit packages. Made from high-impact polystyrene (HIPS) for added strength and durability, our 7” reels are available in a variety of widths, with or without anti-static coatings.

Configuration

LOKREEL® Mini reels have an outside diameter of 7” (178mm) and a 1/2″ (13mm) diameter arbor hole. Reel hubs measure 2” or 2.36” (50mm or 60mm) in diameter and are available in a variety of EIA standard widths from 8 to 32 mm.

Shelf Life and Storage

We recommend that LOKREEL® Mini reels be used within two years from the date of manufacture. Store this product in its original packaging in a climate-controlled environment where temperature ranges from 21° C +/- 17°C (70°F +/- 30°F). Allow the product to stabilize at room temperature prior to use. The mechanical integrity of the product is not affected by humidity.

7″ LOKREEL® Mini Properties

The values presented for this product are typical laboratory data and may be changed without notice.

| Property | Typical Value | Test Method / Standard |

| Tensile Strength | 3,500 PSI | ASTM D-638 |

| Elongation | 40% | ASTM D-638 |

| Flexural Modulus | 280,000 PSI | ASTM D-790 |

| Vicat Softening | 98°C (210°F) | ASTM D-1525 |

| Specific Gravity | 1.04 g/cc | ASTM D-892 |

| Surface Resistivity (Antistatic) | ≤1011 ohms/square | ASTM D 257 Static Dissipative per EIA 541 |

| Surface Resistivity (Standard) | ≤1011 ohms/square | ASTM D 257 |

| White | Blue | Black | |

| 8mm | RD27608 | RD27608-BL | RD27608-BK |

| 12mm | RD27612 | RD27612-BL | RD27612-BK |

| 16mm | RD27616 | RD27616-BL | RD27616-BK |

| 24mm | RD27624 | RD27624-BL | RD27624-BK |

| 32mm | RD27632 | RD27632-BL | RD27632-BK |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

| Product Code | Description | Size (mm) | Pack Size |

| 029-1022 | Flat Punched White Leader Tape | 8 | 100 |

| 029-1023 | Flat Punched White Leader Tape | 12 | 100 |

| 029-1024 | Flat Punched White Leader Tape | 16 | 100 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.