HomeProducts

- +44 (0)1473 836 214

- info@acupaq.com

NEW: Semi Automatic Tape Splice Tool for use with bandolier type shims for increased productivity.

Details:

Watch the NEW tool in action, click here.

| Product Code | Description | Size | Pack Size |

| 029-1039 | Tape Splicing Tool | – | Each |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Many medical manufacturers have come to rely on us to provide them with cost-effective, rigid plastic packaging solutions that work on multiple fronts. Our ISO 9001-2000 compliant quality assurance program and, when appropriate, our Class 1000 (ISO Class 6) clean room, provide the medical packaging containers that keep your devices safe and the quality records that keep your medical packaging program fully traceable.

Our custom package designs will meet your need for fit & function:

We will advise on the raw material selection to assure the performance of your medical packaging containers:

We will create the production protocols and quality assurance elements that your medical packaging may need:

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Product protection, improved ergonomics, reduction of solid waste, and efficient interface with material handling processes are key reasons why manufacturers are moving away from disposable packaging. Our custom thermoformed automation trays perform flawlessly in robotic assembly-lines, they can be pre-engineered in a variety of exterior sizes, with nests designed for the specific part or part family.

Extremely high part positioning precision and automation-compatible pallet design are key factors for flawless insertion and removal by robots. We also understand the importance of protecting and safeguarding your components. We design and develop tray systems that satisfy the requirements of automated material flows and take efficiency considerations into account according to your needs.

Our automation trays, carriers, containers, plastic cases and plastic trays are custom designed for:

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

To protect electronics from moisture and static damage, clear material for easy viewing of content. Applicable to pack electronic products which are sensitive to moisture and static, such as PC board, IC integrated circuit, CD drivers, HD etc.

Features:

| Product Code | Size (inches) | Size (mm) | Pack Size |

| 020-0000 | – | – | 100 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

To protect electronics from moisture and static damage. The bags are opaque and light tight ensuring the inside item can not been seen from outside. Applicable to pack electronic products which are sensitive to moisture and static, such as PC board, IC integrated circuit, CD drivers, HD etc.

Features:

| Product Code | Size (inches) | Size (mm) | Pack Size |

| 018-0412 | 6 x 26 | 152.4 x 660.4 | 100 |

| 018-0413 | 10 x 20 | 254 x 508 | 100 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

To protect electronics from moisture and static damage. The bags are opaque and light tight ensuring the inside item can not been seen from outside. Applicable to pack electronic products which are sensitive to moisture and static, such as PC board, IC integrated circuit, CD drivers, HD etc.

Features:

| Product Code | Size (inches) | Size (mm) | Pack Size |

| 018-0404 | 6 x 26 | 152.4 x 660.4 | 100 |

| 018-0001 | 6 x 28 | 152.4 x 711.2 | 100 |

| 018-0400 | 10 x 20 | 254 x 508 | 100 |

| 018-0401 | 10 x 24 | 254 x 610 | 100 |

| 018-0301 | 10 x 26 | 254 x 660.4 | 100 |

| 018-0402 | 12 x 20 | 304.8 x 508 | 100 |

| 018-0007 | 16 x 18 | 406 x 457 | 100 |

| 018-0403 | 18 x 18 | 457 x 457 | 100 |

| 018-0300 | 22 x 24 | 558.8 x 609.6 | 100 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Using silica gel bags is an economic method of protecting moisture damage to products during transport and storage. It is a synthetic substance produced from sodium silicate meaning it has an absorption capacity of 25% (by weight) at a relative humidity of 50% at 25°C. They are perfect for general packaging, as well as electrical / electronic enclosures and communications equipment.

Each of this particular type of silica gel bag is filled with non-indicating beaded silica gel and can range in capacity from 1g to 500g. By using them in conjunction with a colour change indicator card (HIC) the relative humidity of the product will be visually available to indicate when if the desiccant is still active. We can also supply silica gel bags that conform to Defense Standard 81-86.

Features:

| Product Code | Nominal Desiccant Content (g) |

Nominal Dimensions (mm) – W x L |

Qty / Box | Nato Stock Number |

| 309-0114 | 1 | 30 x 50 | 4000 / tin | 6850-99-212-5139 |

| 309-0115 | 3 | 30 x 56 | 2500 | – |

| 309-0116 | 5 | 30 x 80 | 1500 | – |

| 309-0117 | 10 | 65 x 75 | 1000 | – |

| 309-0118 | 25 | 100 x 95 | 300 / tin | – |

| 309-0119 | 50 | 85 x 110 | 200 | 6850-99-659-9136 |

| 309-0113 | 100 | 85 x 150 | 100 | – |

| 309-0120 | 250 | 145 x 170 | 50 | – |

| 309-0121 | 500 | 145 x 260 | 30 | – |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

Molecular sieve desiccant bags are excellent for protecting against moisture damage in packaging and equipment applications that require low relative humidity levels. Standard capacities range from 3g to 500g. These are a synthetic material made from alumina silicates, with an absorption capacity of 20% (by weight) at a relative humidity of 50% at 25°C.

Features:

Typical applications:

| Product Code | Nominal Desiccant Content (g) |

Nominal Dimensions (mm) – W x L |

Qty / Box |

| ANTMS/S3163/03 | 3 | 30 x 70 | 2000 |

| ANTMS/B013199 | 5 | 30 x 85 | 1300 |

| ANTMS/D3717/18NI | 10 | 60 x 65 | 800 |

| ANTMS/S9374 | 14 | 40 x 80 | N/A |

| ANTMS/D8226 | 60 | 83 x 145 | 150 |

| ANTMS/D3717/86 | 120 | 88 x 170 | 80 |

| ANTMS/D3717/23 | 225 | 138 x 170 | N/A |

| ANTMS/D9069 | 500 | 138 x 225 | 20 |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

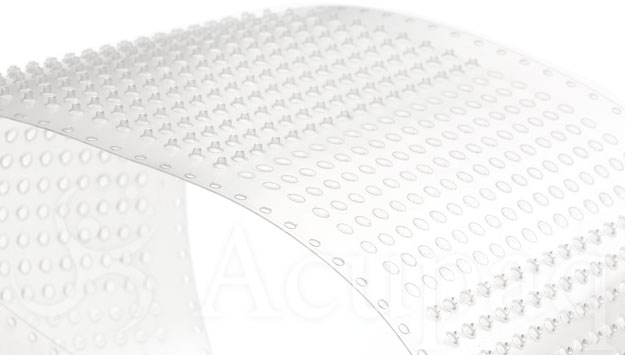

ProFilm™ DL260I Ultraviolet Dicing Tape is designed for use with water jet guided laser dicing systems. This special porous tape is constructed of a chloride-free base film and is wound with a release liner to protect the adhesive layer. ProFilm™ DL260I is nonexpendable and UV curable, providing excellent surface protection, positive wafer and die adhesion and leaves no residue upon removal. These features combine to help contribute to consistent, precise and repeatable wafer production yields.

Construction

ProFilm™ DL2601 is constructed in four layers:

Configurations

ProFilm™ DL260I is available in a variety of configurations. Rolls are 100mm in length, splice-free, and wound on a 3” (75mm) I.D. plastic core. Both custom widths and lengths may be available by special request. ProFilm™ DL260I Ultraviolet Dicing Tape rolls are delivered in a UV blocking polybag and individually boxed.

Shelf Life and Storage

ProFilm™ DL260I Ultraviolet Laser Dicing Tapes should be stored in a climate controlled environment where conditions do not exceed 25°C (75°F). This product is sensitive to UV light, so keep away from heat and direct sunlight. If stored as recommended the product will yield a shelf life of 12 months from the date of manufacture found on the core label and ensure maximum service life of the product.

ProFilm DL260l Material Properties

* Bond Test on Stainless Steel Wafer at 180° peel angle and 300mm/min peel and stretching speed. The values presented for this product are typical laboratory data and may be changed without notice.

| Property | Typical Value | Test Method / Standard |

| Adhesive Strength 1 | Before UV 200 gms After UV 20 gms |

ASM D 1000 |

| Bone Test | Mirror Polished Silicon Wafer | – |

| UV Exposure | 500 mJ/cm2 (recommended UV exposure) |

– |

| Peel Angle | 180° | – |

| Peel & Stretching Speed | 300 mm/min. | – |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.

ProFilm™ DU177E is a protective surface film designed to deliver consistent, precise and repeatable wafer production yields. Enhanced with superior ultraviolet adhesive coating technology, ProFilm™ DU177E offers Total Thickness Variation (TTV) control, expandable base film, and a special low extractable release liner that reduces silicon residue by a significant margin.

Construction

ProFilm™ DU177E is constructed in three layers:

Configurations

ProFilm™ DU177E is available in a variety of configurations. Standard widths include 200mm, 230mm, 250mm, 275mm, 300mm, 330mm and 400mm. Rolls are provided in splice free lengths of 100m on a 3” I.D. plastic core. Both custom widths and lengths may be available by special request. ProFilm™ DU177E rolls are polybag wrapped and individually boxed.

Shelf Life and Storage

ProFilm™ DU177E should be stored in a climate controlled environment where conditions do not exceed 27°C +/- 10° and 30% RH +/- 20%. This product is sensitive to UV light, so store away from heat and direct sunlight. If stored as recommended, the product will yield a shelf life of 12 months from the date of manufacture found on the core label.

ProFilm DU177E Material Properties

The values presented for this product are typical laboratory data and may be changed without notice.

| Property | Typical Value | Test Method / Standard |

| Adhesive Strength 1 | 750g/25mm min before UV (20 min.) 20g/25mm after UV2 |

ASM D 1000 |

| Tensile Strength | 13 N/mm2 MD 9 N/mm2 MD |

ASTM D 882 |

| Elongation | >600% MD >600% TD |

ASTM D 882 |

| Thickness w/o Release Liner | 177μ (3.9 mils) | ASTM D 1005 |

| Temperature Resistance | >5 min. @ 40-45°C | – |

For further information on this product please contact us, one of our experienced sales advisors will be in touch shortly.